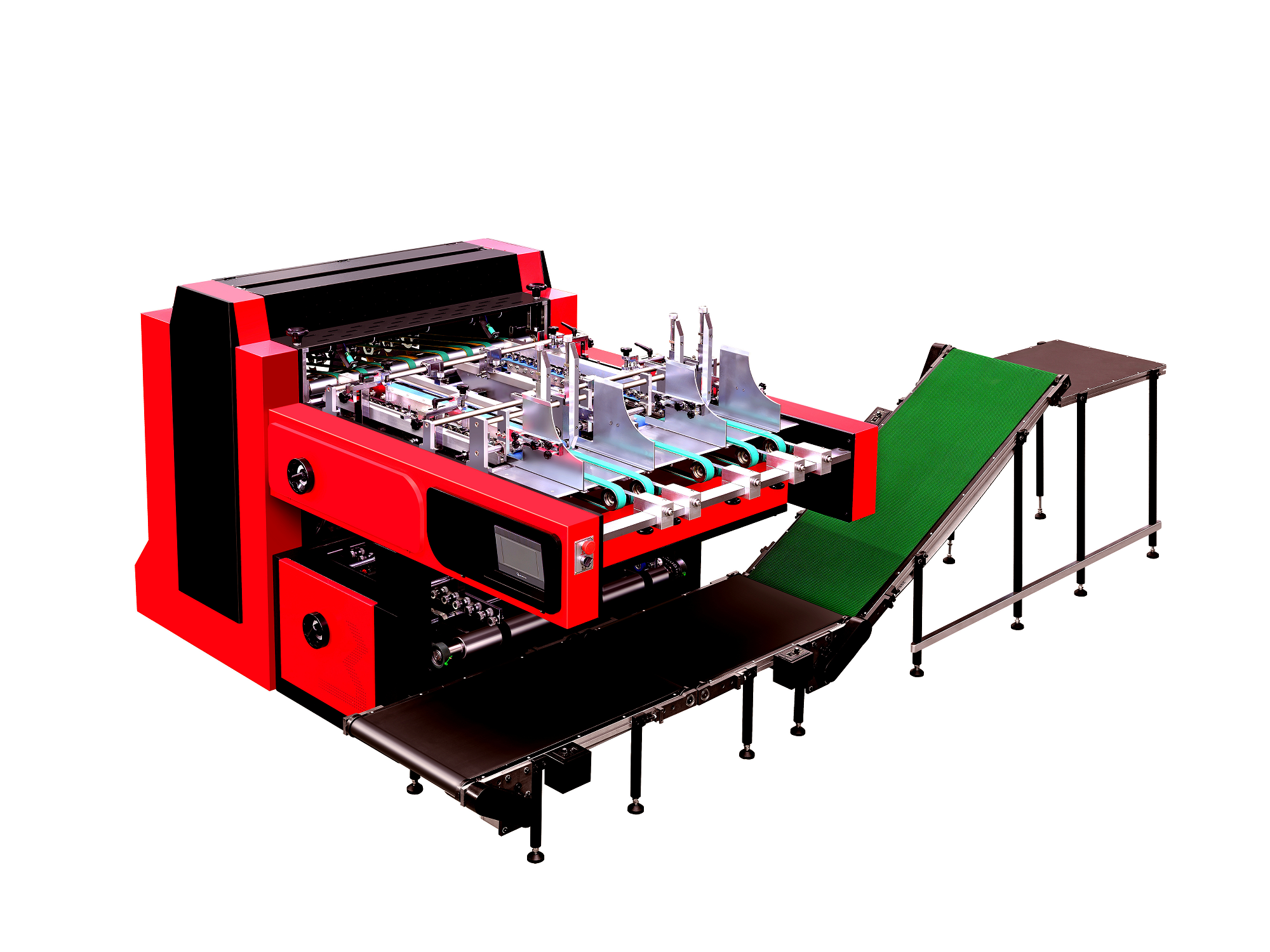

Automatic Grooving Machine SPGM1000-C

The machine is mainly used for making V groove on ash cardboard, copperplate paper, glossy paper, mounted cardboard, paper board and MDF board etc.

Introduction

The machine is mainly used for making V groove on ash cardboard, copperplate paper, glossy paper, mounted cardboard, paper board and MDF board etc.

Technical Parameters

|

Width Of Work Piece |

130-900mm |

|

Length Of Work Piece |

130-700mm |

|

Groove Gap |

2-800mm |

|

Material Thickness |

300gsm-3.4mm |

|

Groove Degree |

80°-140° adjustable |

|

Total Number Of Groove |

9 |

|

Speed |

30-40pcs/min |

|

Best Accuracy (mm) |

±0.05 |

|

Normal Error (mm) |

±0.1 |

|

Total Number Of Groove |

9 |

|

Power Consumption |

2.2 kW |

|

Dimension (mm) L×W×H |

1500×1400×2300 |

|

Weight |

1500kg |

Welcome to our website! Please send your words at any time in the following form and ask us, we will contact you and provide you with the corresponding service as soon as possible. Please write in English.

Box Wrapper SPYD-450H

Automatic mould adjusting to satisfy producing different size box

Adjust mould without changing blister plate and blade for shortening the adjusting time half (It just cost 10-15min. For old version, it will cost 20-30min)

Fold ears, wrap, insert and form the box automatically in one lot

Automatic Side Seal Shrink Wrappers

It is widely used in packaging requirement for batch production, high efficiency, auto film feeding and punching, auto film wrapping, sealing and cutting, manual adjust film guiding system and in-feeding conveyor for different width and height product. Apply to daily necessities, food, cosmetics, pharmaceutical, hardware and other industries shrinking packaging.

Learn MoreHoneycomb Wrapping Paper Making Machine

Honeycomb paper wrap is an easy to utilize alternative to bubble wrap to add padding and protection. A little tug on the roll activates the honeycomb and you are ready to wrap. Honeycomb wrap is available in a variety of different colors to to help personalize your package, creating a protective visually appealing box or mailer filler that also helps to protect your item during shipment. Made from kraft paper, this product is both 100% recyclable and biodegradable.

Learn MorePP STRAP

PP STRAP strapping machine is suitable for the strapping and packing of conventional objects and all kinds of cartons

Learn More