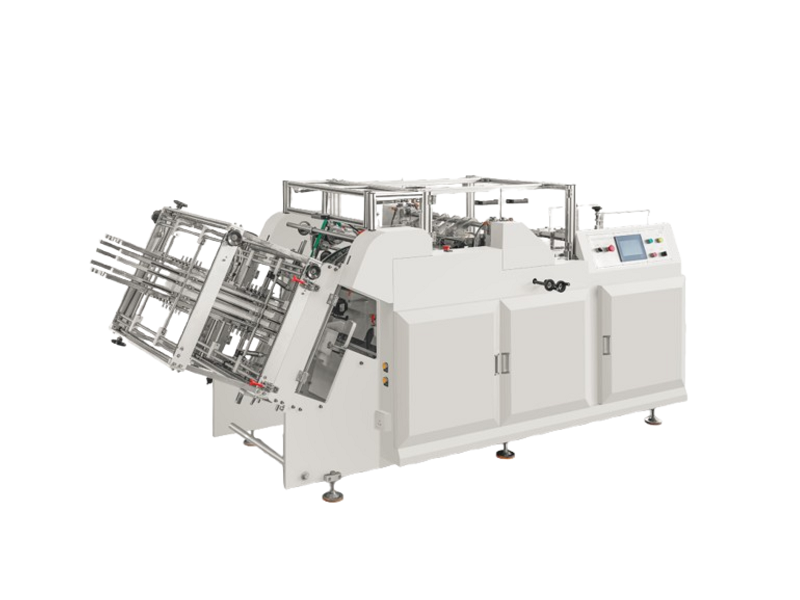

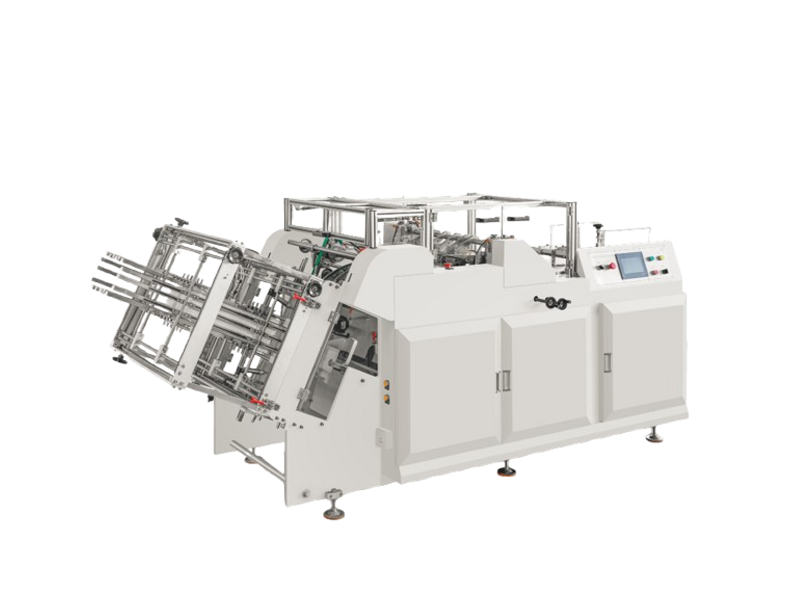

Carton Erecting Machine LT800

New-generation three-dimensional box machine is molding equipment specialized in producing various paper products, which can produce hamburger box, square box, food box (portable outside), and other boxes made by paperboard and corrugated paper, brochures, package boxes, hand-bags, etc.

Introduction

New-generation three-dimensional box machine is molding equipment specialized in producing various paper products, which can produce hamburger box, square box, food box (portable outside), and other boxes made by paperboard and corrugated paper, brochures, package boxes, hand-bags, etc

Features

Servo motor control the forming mold (press mold) (advanced, more accurate than mechanism cam control)

Using full servo system (4 servos in machine replace cam system)

Easy exchange molds to make different products, charging and adjusting time is very short

PLC program control the whole line, available to make complicated boxes

Automatic collection, stock, and count

Human being designed control button and panel, more easy and safe runs by user

PLC could save the adjusted parameter after you finish adjustment, it will help you save time

Technical Parameters

|

Model |

LT800 |

|

Paper Format |

L: 100-480mm W:100-650mm H:15-320mm Angle:5-50° |

|

Paper Range |

Cardboard: 200-600g/m2 Corrugated≤1.5mm(max) |

|

Speed |

50-200pieces/min |

|

Power Consumption |

5kW |

|

Weight |

2000kg |

|

Dimension |

3600×1600×1700mm |

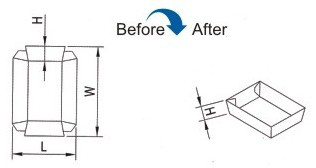

Finished Product

Welcome to our website! Please send your words at any time in the following form and ask us, we will contact you and provide you with the corresponding service as soon as possible. Please write in English.

Carton Erecting Machine LT800

New-generation three-dimensional box machine is molding equipment specialized in producing various paper products, which can produce hamburger box, square box, food box (portable outside), and other boxes made by paperboard and corrugated paper, brochures, package boxes, hand-bags, etc.

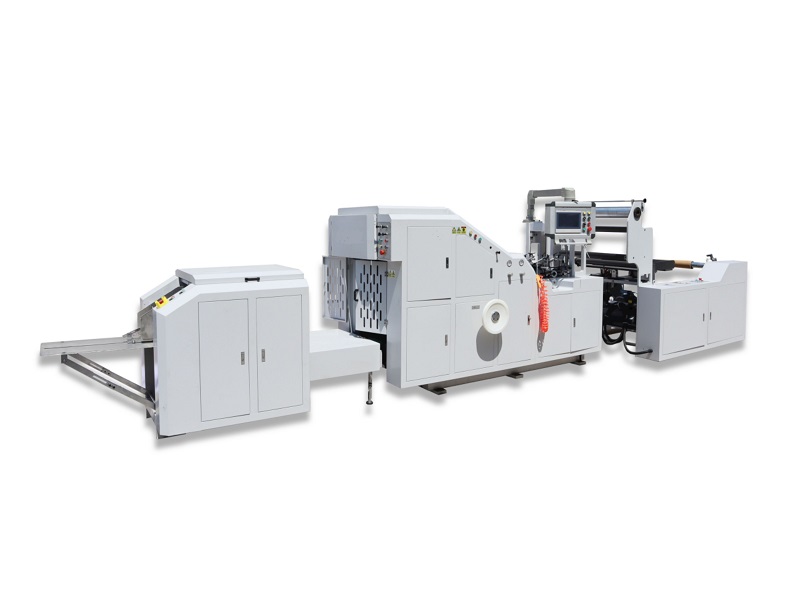

Learn MoreSquare Bottom Paper Bag Making Machine

This roll fed flat handle paper bag making machine is designed for printing roll paper, including primary color paper and kraft paper, as well as completing the production of paper rolls such as food paper in a single process. It offers automatic center gluing, raw material tube formation, length cutting, bottom indentation, and bottom folding. The roll fed flat handle paper bag making machine also applies glue to the bottom and shapes the bottom of the bag. With its convenience, efficiency, and stability, this environmentally friendly paper bag machine produces various types of paper bags, including snack food bags, bread bags, and dried fruit bags, providing a comprehensive bag finishing solution.

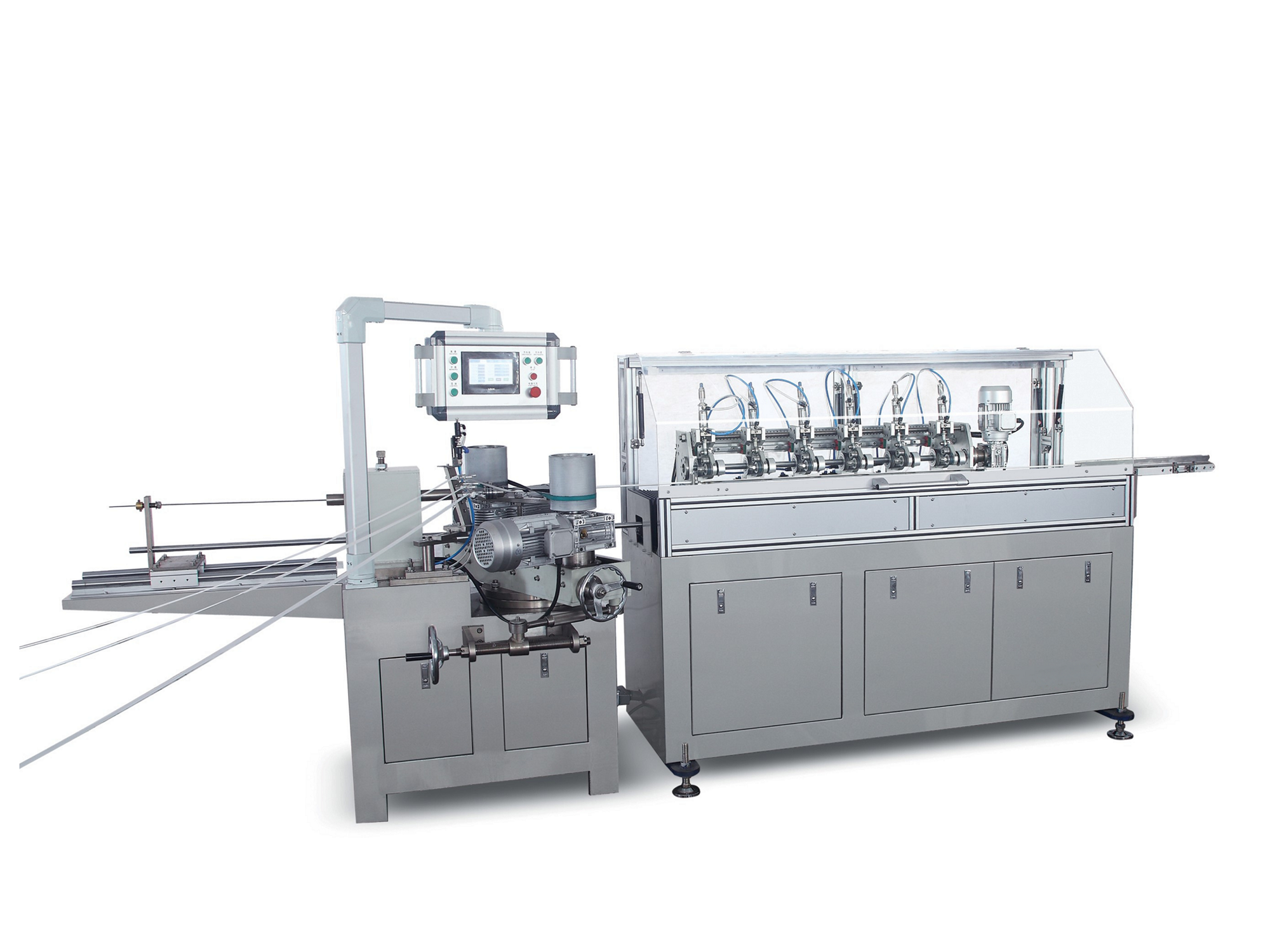

Learn MorePaper Straw Making Machine PSM8-SS

Itintegratesfeeding, gluing, winding, cutting, conveying andcollecting. It is equipped with CNC multi-knife cutting system. It is suitable for 5-12mm diameter paperstraw.

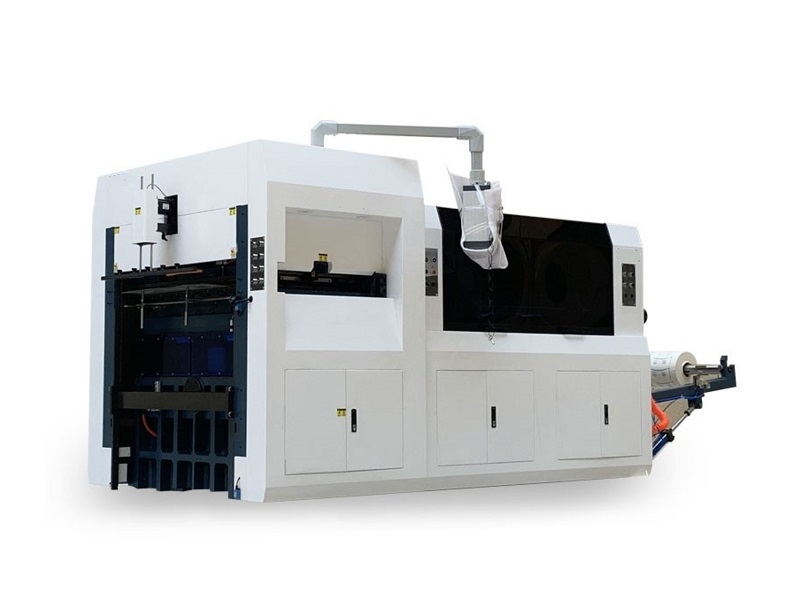

Learn MoreROLLCUT

ROLLCUT is suitable for indentation, die-cutting various cigarette case, kit, paper bowl, food packaging and various paper products. Create precision die cutting all kinds of high-end paper creasing

Learn More