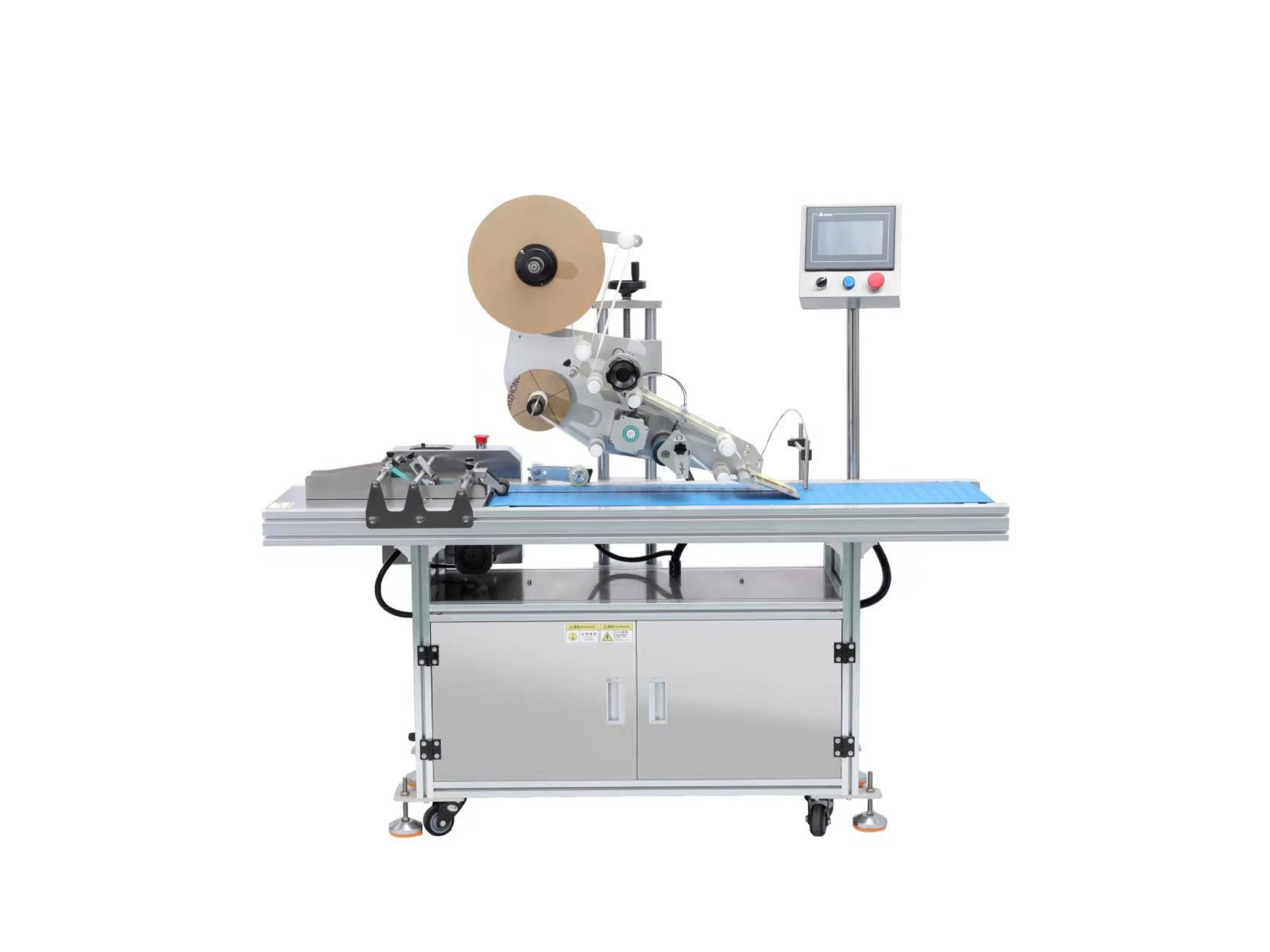

Label applicator for flat surfaces

It is an automatic label applicator that makes it fast and easy to precisely apply product and identification labels onto a wide range of flat surfaces such as carton blanks, packages, bags, pouches, lids, tins and much more. Labels are applied straight without wrinkles or folds in exactly the location desired. This gives finished products a highly professional look and significantly increases the number of containers that can be labeled per hour versus manually applying labels.

Introduction

It is an automatic label applicator that makes it fast and easy to precisely apply product and identification labels onto a wide range of flat surfaces such as carton blanks, packages, bags, pouches, lids, tins and much more. Labels are applied straight without wrinkles or folds in exactly the location desired. This gives finished products a highly professional look and significantly increases the number of containers that can be labeled per hour versus manually applying labels.

Technical Parameters

|

Max. Feeding Product Size (mm) |

(L)300×(W)220×(H)150 |

|

Speed (pcs/min) |

1-50 |

|

Labeling precision (mm) |

±1 |

|

Electric Supply |

AC220V 1P 0.91kW |

|

Weight (kg) |

150 |

|

Dimension (mm) |

(L)1500×(W)600×(H)1600 |

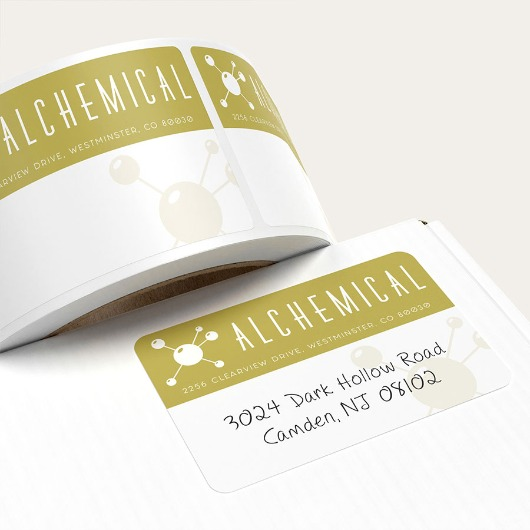

Finished Product

Welcome to our website! Please send your words at any time in the following form and ask us, we will contact you and provide you with the corresponding service as soon as possible. Please write in English.

Carton Sealer

Carton sealers automatically place adhesive tape to the top & bottom of the box simultaneously. The operator simply folds flaps of the corrugated carton and feeds it into the machine. Our carton sealers are reliable, cost-effective and durable providing savings to your production process. Our carton sealers are integral to end of the line production and can provide significant material and labor savings

Automatic Side Seal Shrink Wrappers

It is widely used in packaging requirement for batch production, high efficiency, auto film feeding and punching, auto film wrapping, sealing and cutting, manual adjust film guiding system and in-feeding conveyor for different width and height product. Apply to daily necessities, food, cosmetics, pharmaceutical, hardware and other industries shrinking packaging.

Learn MoreLabel applicator for flat surfaces

It is an automatic label applicator that makes it fast and easy to precisely apply product and identification labels onto a wide range of flat surfaces such as carton blanks, packages, bags, pouches, lids, tins and much more. Labels are applied straight without wrinkles or folds in exactly the location desired. This gives finished products a highly professional look and significantly increases the number of containers that can be labeled per hour versus manually applying labels.

Learn MoreHoneycomb Wrapping Paper Making Machine

Honeycomb paper wrap is an easy to utilize alternative to bubble wrap to add padding and protection. A little tug on the roll activates the honeycomb and you are ready to wrap. Honeycomb wrap is available in a variety of different colors to to help personalize your package, creating a protective visually appealing box or mailer filler that also helps to protect your item during shipment. Made from kraft paper, this product is both 100% recyclable and biodegradable.

Learn More